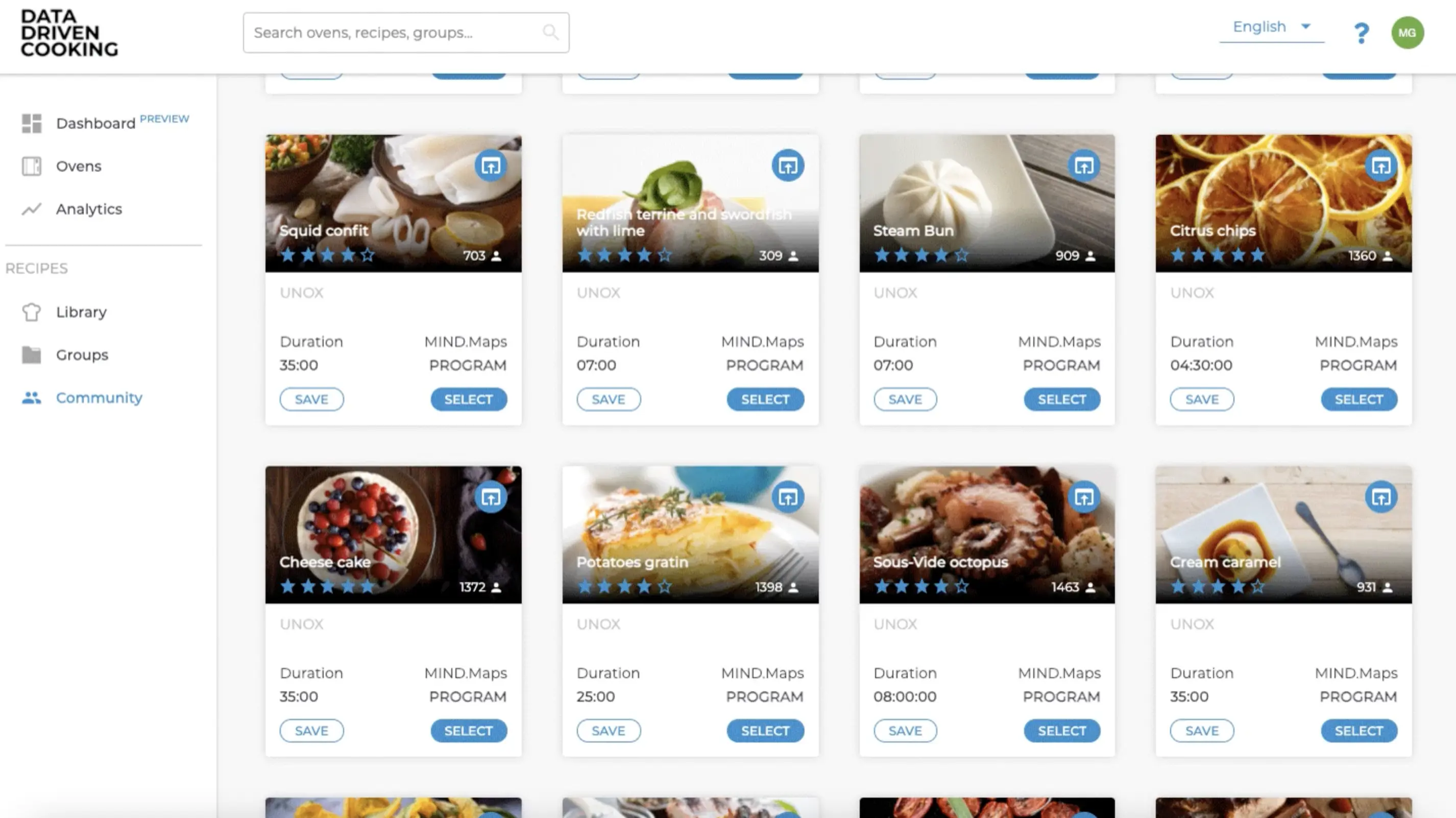

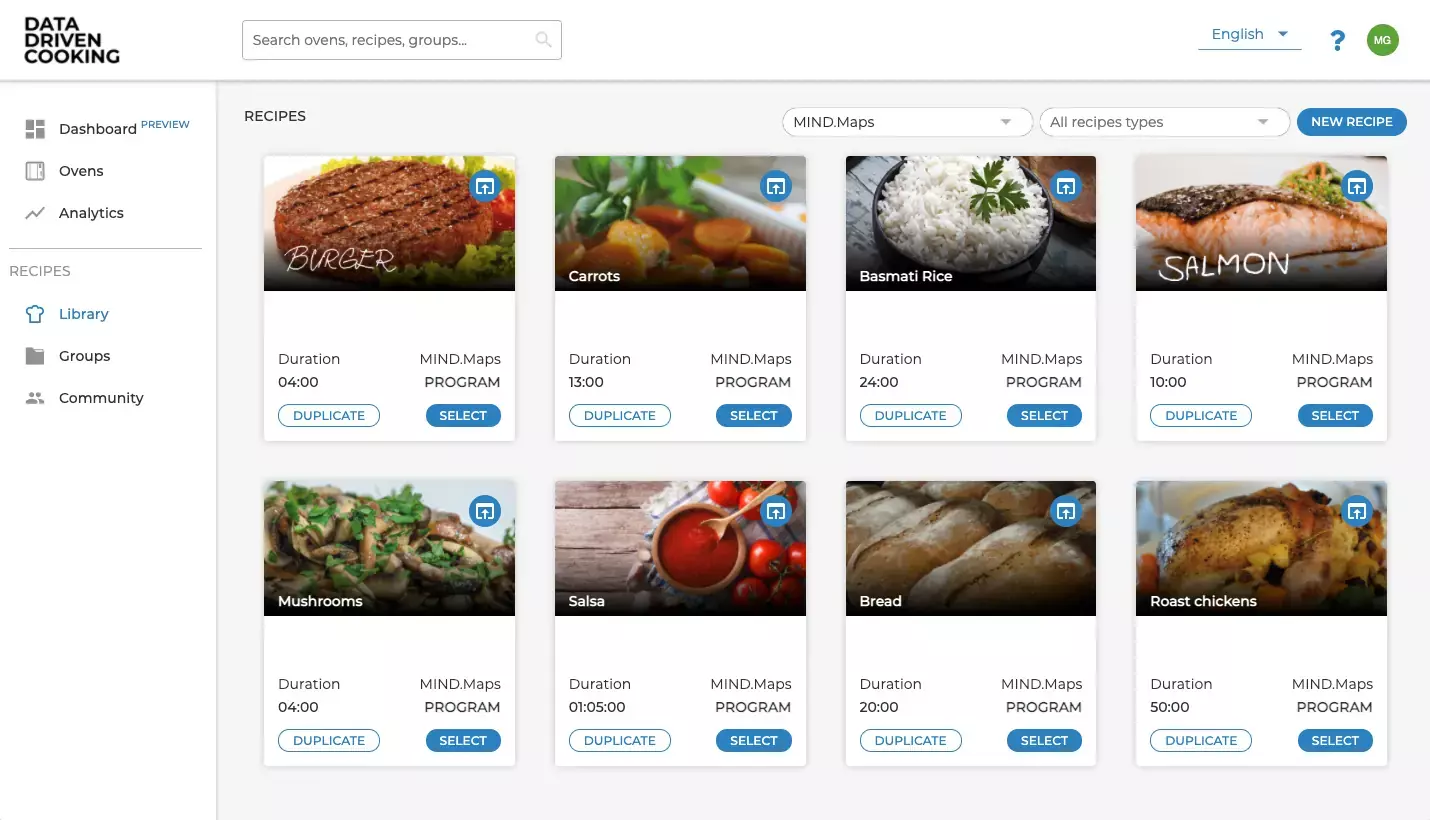

We designed and developed a new environment for Data Driven Cooking (DDC): an oven–connected platform that automates rote aspects of food preparation. Within DDC, smart features generate data that can be analyzed to optimize production. For example: a chef can save tried and true settings (e.g. 40 minutes at 425° for roast chicken) as "recipes" to standardize fare and make it available for analysis. Observing trends over time on DDC—say, the popularity of chicken dinners on Sundays—users can plan ahead for demand.

For overseers of complex and/or large scale operations, the benefits of DDC are manifold. In addition to monitoring the performance of menu items, managers can deduce areas of overlap and suggest cooking schedules that make the most of oven space and reduce energy costs. They can provide failsafe guidance (and effectively operate units remotely) by sending recipes straight to ovens. Beyond cooking, supervisors can keep track of bigger picture considerations—such as the age of units and time between cleanings—to keep business running smoothly.